Spongy

1. Supermacroporous hydrogels

Hydrogels with pores larger than 1 μm are called supermacroporous (SMP) hydrogels to distinguish them from the macroporous polymer networks with pores ranging from 50 nm to 1 μm as defined by the International Union of Pure and Applied Chemistry (IUPAC). Supermacroporous hydrogels, possessing a spongelike structure and permeability, have drawn significant attention for their bioengineering and biomedical applications. However, their mechanical weakness due to the low-density structure is often, but not always, one of their biggest limitations. The mechanical weakness of SMP hydrogels is mainly because of two reasons. First, the mechanical strength of a material decreases with an increase in the volume fraction of pores. The pores are considered as defects in the bulk materials, through which cracks are initiated. Second, the supermacroporous hydrogels are usually made of single-network (SN) hydrogels that are intrinsically weak materials because of the lack of energy dissipation mechanisms. Accordingly, a straightforward strategy to improve the mechanical strength of porous hydrogels is to use high-strength hydrogels together with a suitable preparation technique.

2. The TOUGHEST supermacroporous hydrogels

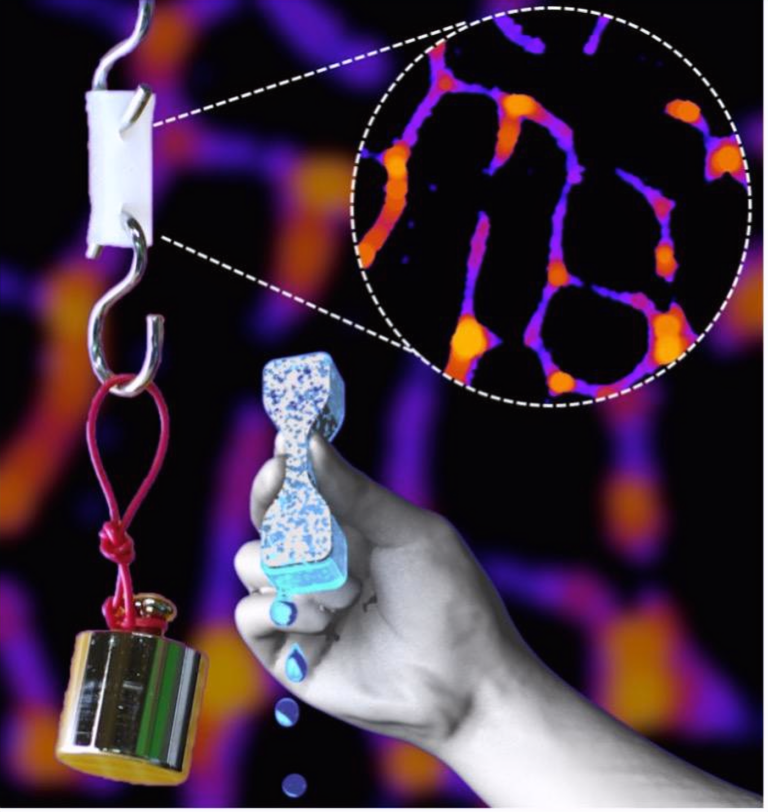

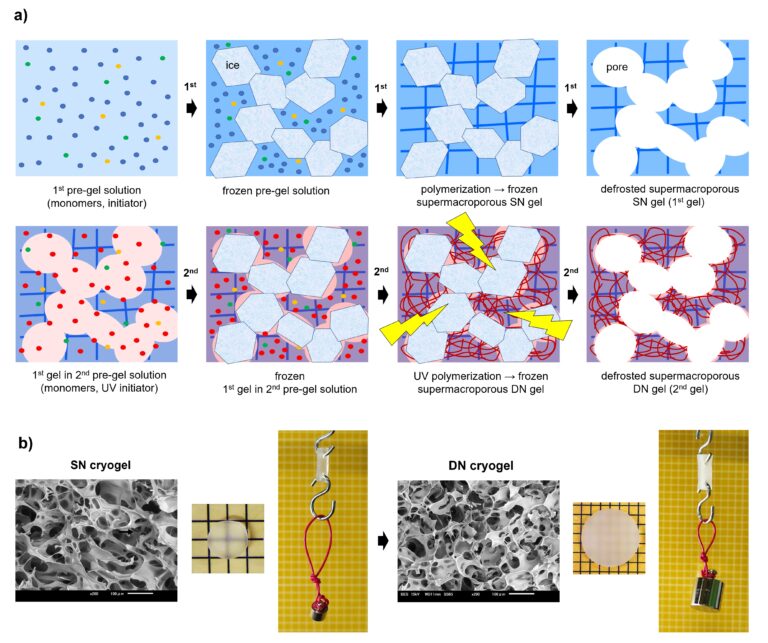

In our recent work [1], we have reported a multistep cryogelation technique, meaning gelation in a frozen state, for preparing tough SMP hydrogels on the basis of the double-network (DN) strategy that was invented in our laboratory in 2003 [2]. The preparation technique is depicted in Scheme 1. The produced SMP DN gels possessed interconnected pores with pore sizes of 50–230 μm. They also showed a compressive modulus of up to ∼100 kPa, which was 2–4 times higher than that of the corresponding SMP single-network (SN) gels, and compressive strength of up to 1 MPa at 80% compression. The DN cryogels were also stretchable with a work of extension of up to 38 kJ m–3, which is 1–2 orders larger than that of the SN cryogels. Their high stiffness and stretchability distinguished them from other types of cryogels, such us hybrid cryogels or common IPN cryogels. We suggest that the developed technique is suitable for preparing SMP DN gels from various polymers; hence, it is promising in meeting different bioengineering and biomedical demands. To the best of our knowledge, DN cryogels based on PNaAMPS and PAAm are the toughest cryogels with open-cell morphology reported.

A video showing the properties of DN cryogels in comparison to corresponding SN cryogels

Scheme 1. Schematic representation of the two-step cryogelation to prepare SMP DN Gels: The 1st polyelectrolyte network is based on sodium 2-acrylamido-2-methylpropane sulfonate (NaAMPS) as a monomer and N,N′-methylenebis(acrylamide) as a crosslinker. The 2nd neutral network is based on acrylamide (AAm) as a monomer and MBAAm. The UV initiation is utilized in the 2nd cryogelation step to ensure that gelation occurs after freezing and so that the SMP morphology of the 1st hydrogel is maintained.

References

- Sedlačík, T.; Nonoyama, T.; Guo, H.; Kiyama, R.; Nakajima, T.; Takeda, Y., Kurokawa, T.; Gong, J. P. Preparation of tough double- and triple-network supermacroporous hydrogels through repeated cryogelation. Chem Mater 2020, 32, 19 8576-8586.

- Gong, J.; Katsuyama, Y.; Kurokawa, T.; Osada, Y. Double-Network Hydrogels with Extremely High Mechanical Strength.Adv. Mater. 2003, 15, 1155– 1158.